Transformer Oil Regeneration

DC-12R Transformer Oil Regeneration Machine

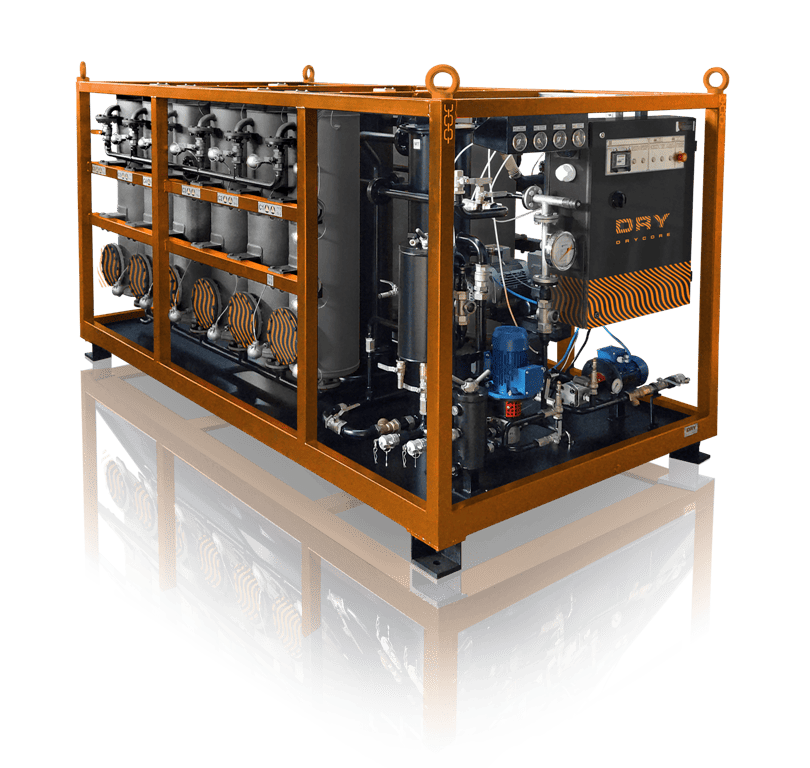

The DC-12R unit is designed for the regeneration of transformer and other types of electrical insulating oils. In this context, “regeneration” refers to the restoration of the operational properties of used oils to the parameters and condition of new ones. The regeneration process is carried out by passing the oil through twelve columns, each filled with a special sorbent possessing high absorbent properties. This sorbent removes all aging products from the oil, changing its color from dark brown to light yellow and reducing its acid number.

Description

The DC-12R unit is designed for the regeneration of transformer and other types of electrical insulating oils. In this context, “regeneration” refers to the restoration of the operational properties of used oils to the parameters and condition of new ones.

The regeneration process is carried out by passing the oil through twelve columns, each filled with a special sorbent possessing high absorbent properties. This sorbent removes all aging products from the oil, changing its color from dark brown to light yellow and reducing its acid number.

If the oil requiring regeneration contains excessive amounts of moisture and dissolved gases, the DC-12R unit can be used together with DC-D series units or, at the customer’s request, can be equipped with additional thermal vacuum drying and degassing modules.

One of the main advantages of the DC-12R unit is the ability to reactivate the sorbent multiple times (up to 500 or more cycles) after it gradually loses its absorbent properties. Thus, the same sorbent can be used repeatedly for the regeneration of new volumes of used oil.

Specification

| No. |

Parameter |

Value |

| 1 | Nominal capacity, gpm (l/h) |

4.4-8.8 (1,000-2,000)* |

| 2 | Oil losses during operation, % |

2-25 |

| 3 | Maximum allowed oil temperature, °F (°C) |

194 (90) |

| 4 | Outlet pressure, psi (bar) |

36.25 (2.5) |

| 5 | Maximum power consumption, kW |

55 |

| 6 | Rated vacuum suction speed, gpm (l/h) |

1,232.8 (280,000) |

| 7 | Sorbent’s mass, lbs (kg) |

3,527.4 (1,600) |

| 8 | Electrical power parameters | |

| Voltage, V |

Customizable |

|

| Frequency, Hz | ||

| 9 | Coarse filtration fineness (mesh filter), µm |

100 |

| 10 | Pre-filtration fineness, µm |

25 |

| 11 | Fine filtration fineness, µm |

5 |

| 12 | Dimensions, in (mm) | |

| Length |

217 (5,500) |

|

| Width |

91 (2,320) |

|

| Height |

96 (2,450) |

|

| 13 | Weight, lbs (kg) |

13,227 (6,000) |

* – nominal capacity of the machine depends on the type and condition of the oil being processed

Benefits

Key Benefits of the DC-12R

- Extended Sorbent Life: The DC-12R regeneration machine allows sorbent beds to be reused up to 500 times or more before replacement is required.

- Reduced Maintenance Effort: Operators no longer need to manually handle large quantities of sorbent each day, simplifying routine maintenance and reducing physical workload.

- Significant Cost Savings: Reuse of sorbent minimizes the expenses associated with purchasing new materials, oil losses, and waste disposal – resulting in substantial long-term operational savings.

- Environmental Sustainability: No need for sorbent disposal or specialized dumping equipment eliminates waste streams and prevents soil and air contamination.

- Enhanced Transformer Reliability: Regular regeneration with the DC-12R machine restores oil parameters to new condition, ensuring better insulation, cooling, and overall reliability of transformers.

- Improved Equipment Longevity: Clean, regenerated oil significantly extends the service life of transformers and other power equipment, reducing downtime and unplanned repair costs.

- Operational Efficiency: The system’s design supports continuous, efficient regeneration cycles with minimal supervision and maintenance requirements.

Details

1

Description

The DC-12R unit is designed for the regeneration of transformer and other types of electrical insulating oils. In this context, “regeneration” refers to the restoration of the operational properties of used oils to the parameters and condition of new ones.

The regeneration process is carried out by passing the oil through twelve columns, each filled with a special sorbent possessing high absorbent properties. This sorbent removes all aging products from the oil, changing its color from dark brown to light yellow and reducing its acid number.

If the oil requiring regeneration contains excessive amounts of moisture and dissolved gases, the DC-12R unit can be used together with DC-D series units or, at the customer’s request, can be equipped with additional thermal vacuum drying and degassing modules.

One of the main advantages of the DC-12R unit is the ability to reactivate the sorbent multiple times (up to 500 or more cycles) after it gradually loses its absorbent properties. Thus, the same sorbent can be used repeatedly for the regeneration of new volumes of used oil.

2

Specification

| No. |

Parameter |

Value |

| 1 | Nominal capacity, gpm (l/h) |

4.4-8.8 (1,000-2,000)* |

| 2 | Oil losses during operation, % |

2-25 |

| 3 | Maximum allowed oil temperature, °F (°C) |

194 (90) |

| 4 | Outlet pressure, psi (bar) |

36.25 (2.5) |

| 5 | Maximum power consumption, kW |

55 |

| 6 | Rated vacuum suction speed, gpm (l/h) |

1,232.8 (280,000) |

| 7 | Sorbent’s mass, lbs (kg) |

3,527.4 (1,600) |

| 8 | Electrical power parameters | |

| Voltage, V |

Customizable |

|

| Frequency, Hz | ||

| 9 | Coarse filtration fineness (mesh filter), µm |

100 |

| 10 | Pre-filtration fineness, µm |

25 |

| 11 | Fine filtration fineness, µm |

5 |

| 12 | Dimensions, in (mm) | |

| Length |

217 (5,500) |

|

| Width |

91 (2,320) |

|

| Height |

96 (2,450) |

|

| 13 | Weight, lbs (kg) |

13,227 (6,000) |

* – nominal capacity of the machine depends on the type and condition of the oil being processed

3

Benefits

Key Benefits of the DC-12R

- Extended Sorbent Life: The DC-12R regeneration machine allows sorbent beds to be reused up to 500 times or more before replacement is required.

- Reduced Maintenance Effort: Operators no longer need to manually handle large quantities of sorbent each day, simplifying routine maintenance and reducing physical workload.

- Significant Cost Savings: Reuse of sorbent minimizes the expenses associated with purchasing new materials, oil losses, and waste disposal – resulting in substantial long-term operational savings.

- Environmental Sustainability: No need for sorbent disposal or specialized dumping equipment eliminates waste streams and prevents soil and air contamination.

- Enhanced Transformer Reliability: Regular regeneration with the DC-12R machine restores oil parameters to new condition, ensuring better insulation, cooling, and overall reliability of transformers.

- Improved Equipment Longevity: Clean, regenerated oil significantly extends the service life of transformers and other power equipment, reducing downtime and unplanned repair costs.

- Operational Efficiency: The system’s design supports continuous, efficient regeneration cycles with minimal supervision and maintenance requirements.