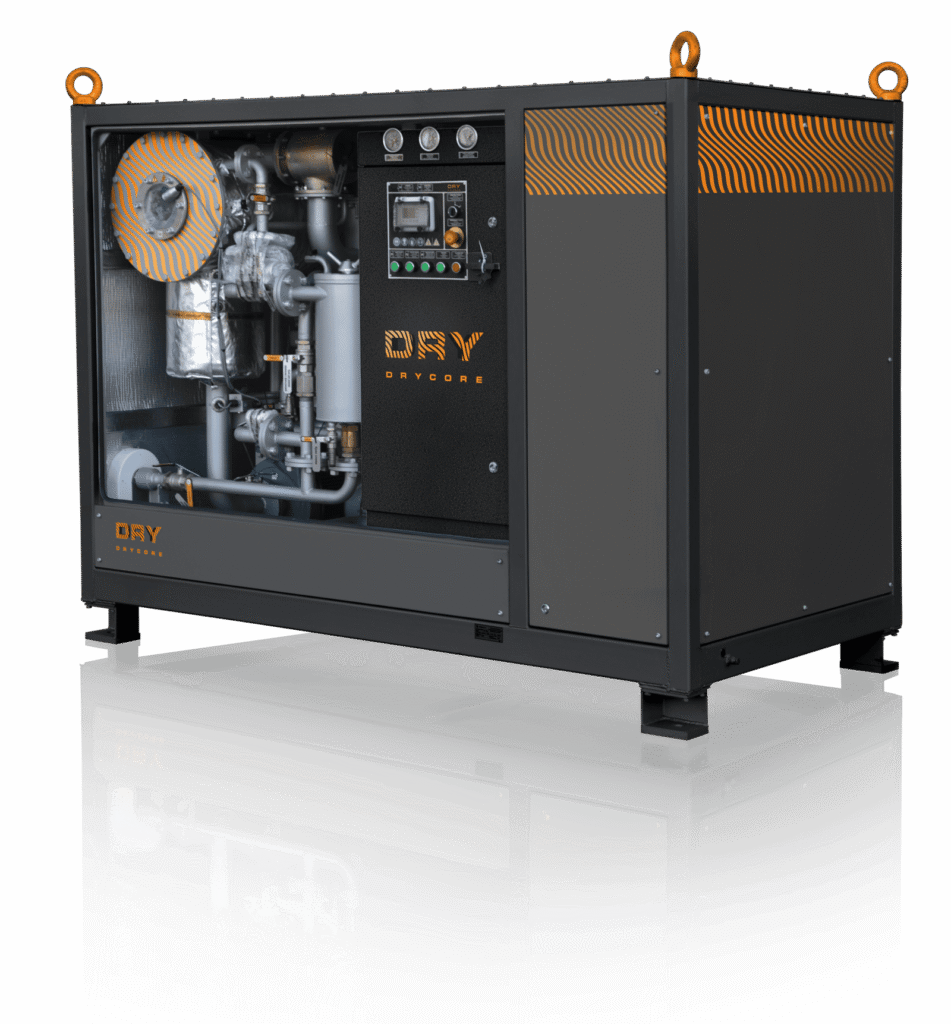

Transformer Oil Purification Plant Dry Core

The transformer oil purification plant Dry Core is designed to ensure reliable operation of power and high-voltage equipment where the oil functions as both liquid insulation and a heat-transfer medium. In transformers, OLTCs, power cables, and high-voltage capacitors, transformer oil provides the dielectric strength of the insulation system and effective heat dissipation. However, during equipment operation, water, gases, oxidation products, and solid particles accumulate in the oil, reducing reliability and shortening the service life of the entire electrical system.

Causes of Transformer Oil Aging and the Hazards of Contamination

Transformer oil produced through deep selective refining of petroleum products has different chemical properties depending on the crude oil source. During operation, even under ideal conditions, the oil oxidizes in the presence of oxygen and water. This triggers the formation of acids, aldehydes, alcohols, and other compounds that create acidic sludge—heavy contaminants that deposit on insulation surfaces.

Such deposits increase oil viscosity and reduce its heat capacity, resulting in poorer transformer cooling, especially during high-load operation. As a result, the transformer heats up more quickly, ages faster, and loses its operational life.

Water is especially dangerous: even 0.001% water significantly reduces breakdown voltage. In oil, water may exist in three states—dissolved, droplet, and emulsified. The equilibrium between these states depends on temperature, pressure, and additives. Any disturbance of this balance leads to rapid deterioration of the oil’s dielectric properties.

For this reason, the transformer oil purification plant becomes one of the key elements in maintaining high-voltage equipment.

Transformer Oil Purification Plant Dry Core and Its Technological Role

The transformer oil purification plant Dry Core (DC-18D) is a mobile unit designed for comprehensive purification of transformer and electrical-insulating oil from:

• mechanical impurities

• water in all three states

• dissolved and free gases

The Dry Core unit is a mobile system combining a heating module, coarse and fine filters, a gear pump, a pipeline system, a vacuum pump, a vacuum chamber, and an electronic control module. Each element performs its own function in forming a multistage purification process.

The oil first passes through a mesh filter that protects the pump from large particles, then enters the heater where its temperature is raised to around 194°F, creating optimal conditions for further vacuum-assisted moisture evaporation.

Next, the oil flows through the coarse filter, which removes larger solid particles, and then enters the vacuum chamber. A low-pressure environment inside the chamber allows water and gases to evaporate intensively even at very low concentrations. The internal baffles have an increased surface area to ensure effective contact between the heated oil and vacuum, speeding up the degassing process.

Water vapor and gases are removed by the vacuum pump, while the dehydrated oil returns to the circulation loop for final fine filtration. At the outlet, the user receives electrical-insulating oil purified from harmful contaminants to standard-compliant levels.

The transformer oil purification plant Dry Core stands out by combining heating, filtration, and thermal-vacuum dehydration. After treatment in this unit, the breakdown voltage of the oil may increase by dozens of percent, while water content decreases to 5 ppm, matching the quality of new transformer fluid. With reduced viscosity and restored heat capacity, the oil dissipates heat more effectively, ensuring stable transformer temperature conditions. This helps extend equipment service life, reduce maintenance needs, and prevent failures caused by insulation degradation.