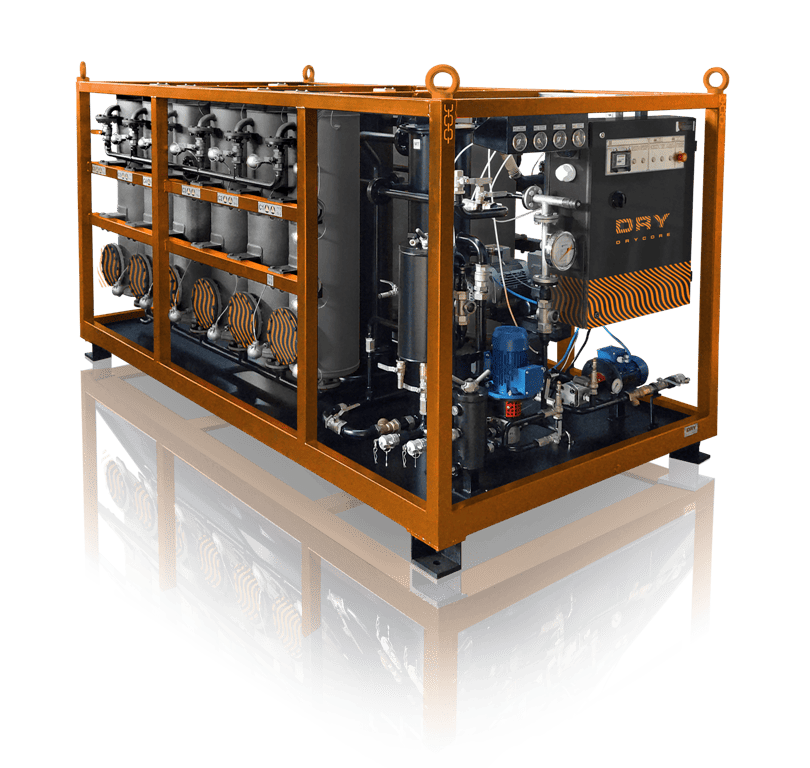

Transformer Oil Regeneration Plant DC-12R

Transformer oil regeneration plant DC-12R is a solution designed to restore the dielectric strength and chemical stability of aged transformer oil. Since the service life of a power transformer largely depends on the condition of its insulation system, maintaining oil purity is essential for reliable operation. The insulation system includes both liquid insulation (transformer oil) and solid (cellulose-based materials). Transformer oil provides around 80% of the electrical strength inside the transformer, while the solid insulation supports the mechanical structure. Studies show that nearly 85% of transformer failures occur due to insulation system degradation — a process that can be effectively slowed or reversed through regular oil regeneration with the DC-12R system.

Transformer oil not only insulates, but also cools the transformer. Its low viscosity enables efficient heat transfer from windings to the cooling system. Stabilized oil resists oxidation and prevents the formation of harmful by-products, thus prolonging transformer life. The transformer oil regeneration plant DC-12R by DryCore is specifically designed to perform this function efficiently, ensuring long-term operational reliability.

Causes of transformer oil aging

The aging or deterioration of transformer oil is primarily caused by oxidation. When oxygen and moisture come into contact with hot oil, chemical reactions occur, producing acids, sludge, and other polar compounds. These contaminants, combined with heat and water, accelerate the degradation of both the oil and the cellulose insulation.

Moisture is particularly harmful. Even a small increase in water content can dramatically shorten insulation life — for example, an insulation system with 1% moisture ages ten times faster than one with only 0.1% moisture. Contaminants such as acids, aldehydes, and alcohols form sludge that settles on the transformer’s walls, coils, and cooling channels. This sludge increases oil viscosity, reduces cooling efficiency, and contributes to overheating and further oxidation.

Transformer oil regeneration plant DC-12R

The transformer oil regeneration plant DC-12R by DryCore, restores used and oxidized transformer oil to its original dielectric and chemical properties. The process is based on continuous circulation of the oil through a regeneration system. Oil is drawn from the bottom of the transformer tank, then passed through a series of adsorption columns that remove aging by-products such as acids, oxidation compounds, and sludge. These contaminants are captured by specialized adsorbent materials that restore the oil’s stability and color. Optionally, after adsorption, the oil undergoes fine filtration and vacuum dehydration in DC-D series units, effectively eliminating remaining moisture and dissolved gases. Once treated, the regenerated oil is returned to the top of the transformer, completing the cycle and allowing the process to continue until the oil meets the required dielectric strength and purity standards.

This process continues until the oil meets standard performance parameters or the desired dielectric strength.

Transformer oil regeneration vs. filtration

It’s important to distinguish between oil regeneration and simple filtration. Filtration only removes mechanical impurities and free water, but it cannot eliminate dissolved oxidation products such as acids, aldehydes, and ketones. As a result, filtration alone cannot restore the oil’s original color or insulating properties. In contrast, regeneration is a comprehensive treatment that removes chemical degradation products, restores the oil’s color, improves its dielectric strength, and brings its characteristics close to those of new oil.

The transformer oil regeneration plant DC-12R is engineered to perform full-scale oil restoration, making it possible to reuse the same oil for decades. When properly maintained, regenerated oil can match new oil in performance and extend transformer service life up to 40–60 years.

Replacing large volumes of transformer oil is expensive and environmentally challenging. Regenerating oil with the DC-12R transformer oil regeneration plant significantly reduces waste, operational costs, and environmental impact. The restored oil can remain in service indefinitely with periodic reprocessing, making it a sustainable and cost-effective alternative to disposal and replacement.