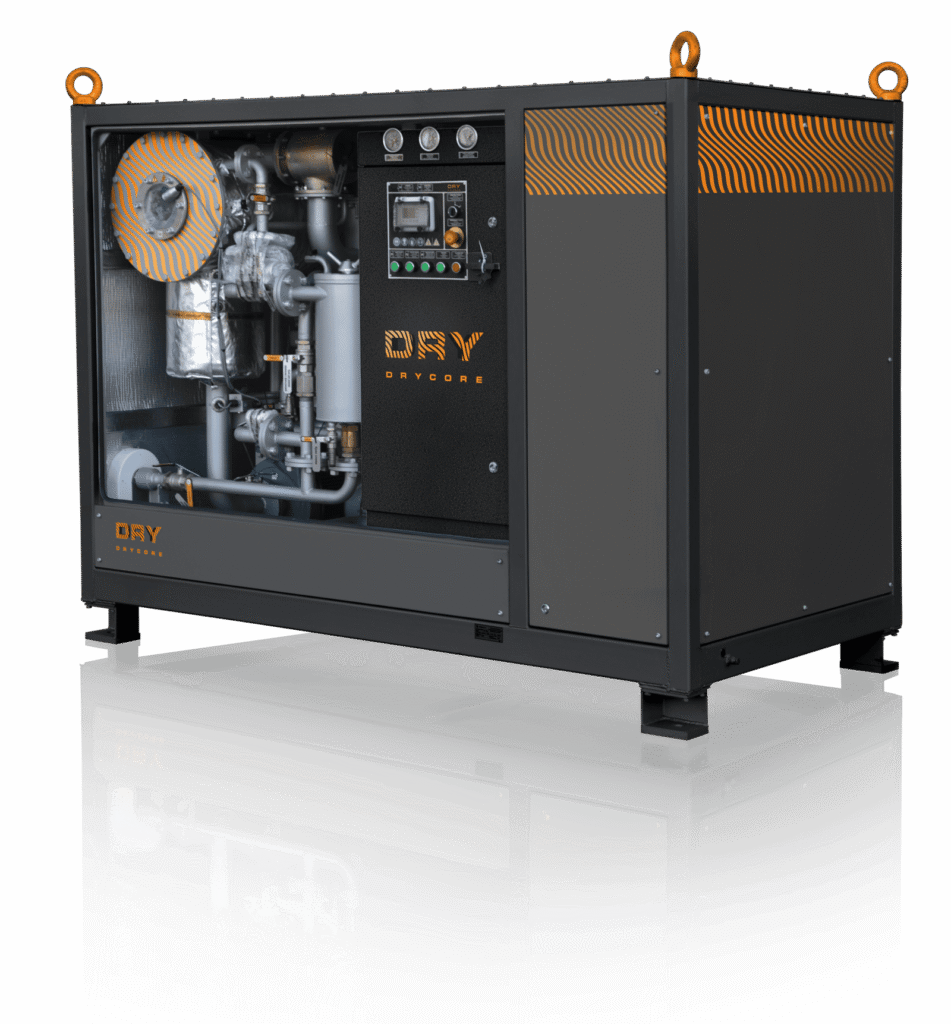

Dry Core Transformer Oil Treatment Plant

The transformer oil treatment plant Dry Core is engineered to address one of the most challenges in high-voltage electrical systems-maintaining the insulating oil in a clean, dry, and gas-free state. As operating voltages of power transformers continue to rise, ensuring proper degassing, drying, and filtration of transformer oil becomes essential to reliability, dielectric strength, and long-term equipment performance. The Dry Core system was developed specifically to meet modern utility-grade standards for transformer installation, servicing, and lifetime asset protection.

Why Transformer Oil Must Be Treated

Transformer oil naturally absorbs air both from the environment and from dissolved gases within the fluid. This internal gas content significantly reduces the dielectric strength of oil and solid insulation, becoming a source of partial discharges that accelerate transformer aging.

Degassing is therefore not simply maintenance-it is a foundational requirement for operational safety. For example, high-voltage transformers rated at 750 kV require evacuation of their tanks to levels below 0.029 psi (1.5 mm Hg) for no less than 72 hours. At a deeper vacuum of 0.019 psi (1 mm Hg) the duration can be shortened to 48 hours. These values illustrate how tightly modern standards regulate vacuum drying and oil degassing as part of safe commissioning procedures.

Gas saturation processes are influenced by oil column height, contact area between oil and gas, vibration inside operating transformers, and thermal conditions. Any local pressure drops inside the oil-especially under vibration-can force dissolved gases to form bubbles, which introduces new high-risk discharge centers.

The Dry Core system is designed to prevent these phenomena by restoring the oil to a stable, low-gas, low-moisture condition.

Understanding Vacuum and Gas Behavior in Oil Processing

To properly degas transformer oil, one must understand how gases behave under vacuum. A pressure below 14.5 psi is defined as vacuum, and industrial systems typically reach low 0.00014–0.019 psi (10–133 Pa), medium 0.019–0.000014 psi (133–0.1 Pa), and high 0.000014–1.45×10⁻⁹ psi (0.1 Pa–10⁻⁴ Pa) vacuum levels.

Gas molecules constantly collide with the walls of the chamber, generating pressure. Reducing this pressure decreases molecular activity, allowing dissolved gases to escape from the oil surface. Vacuum systems also rely heavily on sorption-gas molecules binding to metal surfaces-which is why all internal surfaces must be degassed before deep-vacuum work.

Gas flow through pipelines is influenced by pressure gradients, viscosity, molecular collisions, and the geometry of the vacuum system. Pumping speed, conductance, and residual pressure determine how quickly and effectively gases can be evacuated.

The Dry Core system integrates these principles into a highly controlled vacuum-thermal environment optimized for transformer oil purification.

Core Functions of the Dry Core transformer oil treatment plant

The Dry Core unit performs three essential operations simultaneously:

- Filtration – removal of mechanical impurities and solid particles.

- Degassing – extraction of dissolved gases.

- Drying – removal of moisture and chemically bound water.

In this way, the Dry Core system functions as a complete transformer oil treatment plant, capable of meeting the technical demands of modern power systems.

Filtration Technology

Oil first passes through a coarse filter, which traps large contaminants and protects internal components from damage. This is the initial step of the comprehensive cleaning process.

After degassing and drying, the oil undergoes fine filtration, which may be mechanical or electrostatic. Mechanical elements made from dense polypropylene with 5 μm pore size capture most micro-particles. Their high dirt-holding capacity reduces operating costs and replacement frequency. Electrostatic separation removes even smaller particles, providing ultra-fine purification that mechanical elements cannot achieve alone.

Both coarse and fine filters are designed with serviceability in mind-they can be cleaned or replaced quickly and easily.

Degassing Inside the Dry Core Transformer Oil Treatment Plant

In all Dry Core-based systems, degassing is performed in a thermal-vacuum chamber operating at 5–7 mm Hg. Oil enters the chamber through spray nozzles or foam distributors that dramatically increase its surface area. Under reduced pressure and elevated temperature, gases escape efficiently from the oil.

Removing Moisture and Water from Transformer Oil

The same thermal-vacuum module performs continuous drying. Because water evaporates rapidly under reduced pressure and heat, both moisture and dissolved gases are removed simultaneously.

Heating plays a decisive role: raising the oil temperature to 113°F accelerates moisture evaporation and degassing. For this reason, Dry Core systems equipped with heating modules deliver significantly faster and more complete purification results.

The Dry Core transformer oil treatment plant gives U.S. utilities the ability to maintain their transformer fleets at the highest dielectric standards. By removing moisture, dissolved gases, and particulate contaminants-and by preparing transformer tanks with precise vacuum evacuation-the system significantly increases transformer lifespan, reduces failure rates, and supports long-term grid stability.

If you need assistance selecting the right Dry Core unit for your operation, we’re ready to help you ensure maximum performance and reliability of your electrical assets.