Vacuum dehydration oil purification system

The vacuum dehydration oil purification system serves as the most effective method for removing water and gas contamination from transformer oil, ensuring stable electrical performance and long-term equipment reliability.

Moisture affects both the insulating oil and the cellulose-based solid insulation, reducing their dielectric properties and accelerating aging. In new transformers, the moisture content in solid insulation is typically below 1%. However, during normal operation, it gradually increases and can reach up to 3% after 25 years, exceeding the safe limit of 2%. This increase in water content shortens the cellulose life by nearly half and cause moisture migration into the oil.

How Moisture Affects Transformer Performance

The presence of water in transformer oil results in severe deterioration of electrical and thermal characteristics. Moisture decreases the breakdown voltage, lowers the maximum permissible load, and accelerates oxidation processes. In addition, it can lead to the formation of conductive bridges in the winding insulation and partial discharges under high voltage.

There are two main sources of water in transformer systems:

- External penetration through seals and air intake systems under pressure fluctuations;

- Internal generation, which occurs naturally due to oxidation and cellulose decomposition during transformer aging.

During normal service, moisture continuously migrates between oil and insulation, making real-time control difficult.

Principle of Operation of the Vacuum Dehydration Oil Purification System

The vacuum dehydration oil purification system removes moisture based on the principle of reducing the partial pressure of water vapor. Under vacuum, water boils at much lower temperatures than under atmospheric pressure, allowing it to be separated from oil without damaging its chemical structure.

In practice, transformer oil is heated to around 149–158 °F while the system maintains a vacuum of 635–711 mm Hg. Under these conditions, water evaporates at approximately 122–131 °F and is completely removed from the oil. This process effectively eliminates free, emulsified, and dissolved water, as well as gases and light volatile contaminants.

The result is transformer oil with moisture content below 10 ppm and restored dielectric strength, which significantly extends the service life of both the oil and the transformer.

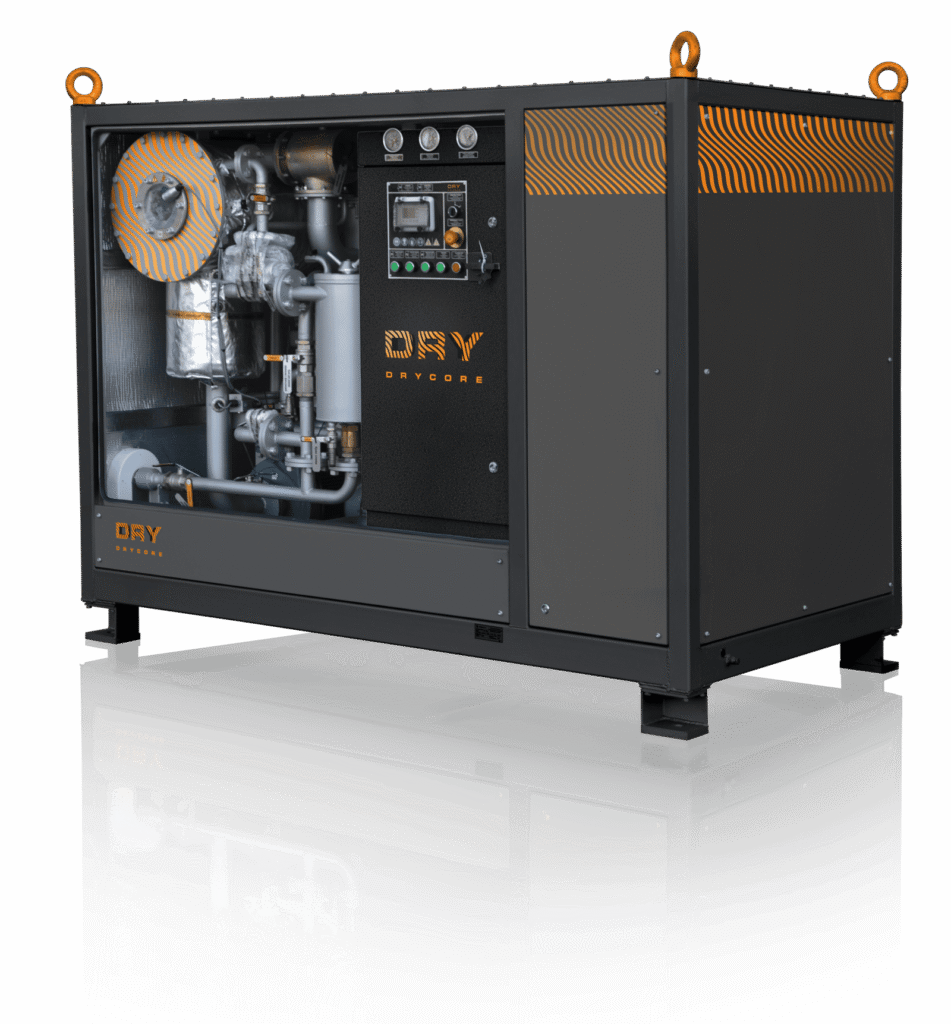

Dry Core Technology

The Dry Core transformer oil drying systems DC are an advanced implementation of the vacuum dehydration oil purification system concept. These units combine vacuum dehydration, fine filtration, and thermal conditioning into a single automated process.

Key Advantages of Dry Core Units:

- Superior drying performance – removes up to 99% of dissolved and emulsified water;

- Temperature-safe treatment – oil heating does not exceed 194ºF, preventing oxidation and preserving additives;

- Gas removal capability – efficiently eliminates air and light gases, improving insulation reliability;

- Energy efficiency – optimized vacuum pumps and heaters minimize energy consumption;

- Continuous operation – compatible with online transformer service;

- Compact design – easy integration into transformer substations and service trailers.

With its vacuum dehydration oil purification system, Dry Core technology allows operators to maintain the moisture balance of transformer oil continuously, preventing emergency conditions and extending maintenance intervals.

From an engineering perspective, the vacuum dehydration oil purification system is the most cost-effective and technically sound solution for maintaining transformer oil quality. Compared to conventional thermal drying or chemical absorbents, vacuum dehydration provides deeper purification and better control over oil properties.

Because water removal occurs at relatively low temperatures, there is no risk of oil oxidation or additive degradation. For high-value equipment such as power transformers, this translates directly into cost savings, longer asset life, and improved power network reliability.

Water contamination in transformer oil is one of the main causes of reduced dielectric performance, accelerated aging, and unexpected failures. The vacuum dehydration oil purification system, particularly in the form of Dry Core technology, provides a highly efficient, safe, and reliable solution for moisture rem