Transformer oil dehydration unit

The transformer oil dehydration unit is designed to address one of the most complex challenges in electrical engineering — the presence of water in transformer oil in multiple associated forms. Modern research shows that in oil-filled electrical equipment, water can exist in four main states: molecularly dissolved, bound, emulsified, and surface (layered). These states are not static — they continuously transform into one another, depending on temperature, electrical field strength, and the chemical composition of the oil.

For example, dissolved and bound water are in a constant dynamic equilibrium; an increase in temperature weakens the hydrogen bonds between water molecules and oil components, leading to a higher amount of dissolved water, while cooling reinforces those bonds, increasing bound water content. However, this process is not instantaneous: heating transformer oil from 77°F to 149°F can take 15–20 days to reach equilibrium, while cooling it back down to 77°F may require 30–40 days. This means that during rapid cooling, water does not have time to revert to its bound state and forms an emulsion — the most dangerous form of moisture, as it drastically reduces the oil’s dielectric strength.

Water Association and Transformation Processes in Transformer Oil

Water in transformer oil forms associations — molecular clusters or hydrogen-bonded structures — that can shift between different states depending on operating conditions. The Transformer oil dehydration unit Dry Core effectively targets all these water associations, breaking them apart through a carefully controlled thermal vacuum drying process.

The oil’s composition plays a vital role in this equilibrium. Components such as aldehydes, ketones, alcohols, acids, and esters produced during oxidation can form strong hydrogen bonds with water molecules. One molecule of such a compound can associate with several to dozens of water molecules. This explains why aged or oxidized oils tend to retain more bound water.

Strong electric fields — up to 4.9 MV/m (≈14.6 kV/in) — also affect these associations, increasing the amount of dissolved water by breaking molecular bonds. Studies have shown that under high electric stress, the concentration of dissolved water can increase three to six times, while carbon dioxide — another oxidation product — rises only twofold. This indicates that electric fields not only intensify oxidation but also promote the conversion of bound water into dissolved form, raising the risk of emulsion formation during cooling and thus increasing the chance of dielectric failure.

The Role of the Transformer Oil Dehydration Unit in Oil Maintenance

The reliability and longevity of transformer operation depend directly on oil quality. A Transformer oil dehydration unit like Dry Core ensures that transformer oil remains clean, dry, and electrically stable. Without proper dehydration, even a small amount of moisture — as low as 0.003% by weight — can drastically reduce breakdown voltage.

Moisture not only decreases dielectric strength but also accelerates oxidation, increases acidity, and promotes sludge formation. Over time, this leads to insulation breakdown, especially in cellulose-based materials. To counter these issues, the oil must maintain low viscosity, high flash point (around 356°F), excellent heat dissipation, and no trace of sulfuric acids or mechanical impurities.

The Thermal Vacuum Principle of the Dry Core Transformer Oil Dehydration Unit

The Dry Core Transformer oil dehydration unit employs a thermal vacuum drying process to remove water and gases from oil without using adsorbents. The process involves:

- Preheating the oil to reduce viscosity and enhance filtration.

- Coarse filtration to remove larger particles and impurities.

- Vacuum dehydration and degassing, where reduced pressure allows moisture and gases to evaporate at lower temperatures.

- Fine filtration at the outlet to ensure optimal purity.

This method ensures deep dehydration and complete degassing, restoring the dielectric properties of transformer oil to near-original quality after a single processing cycle.

Operational Benefits of the Dry Core System

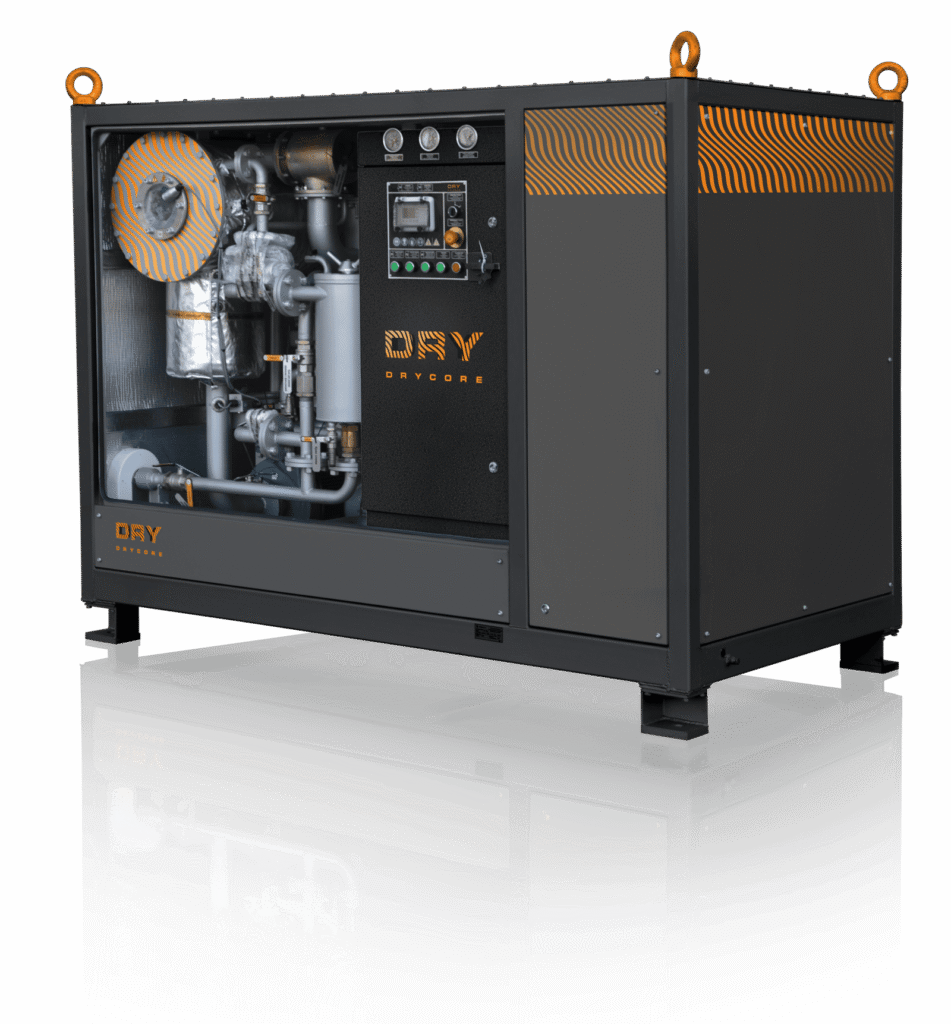

The transformer oil dehydration unit Dry Core combines efficiency, mobility, and environmental safety:

- Comprehensive functionality: Heating, filtration, degassing, dehydration, and vacuum evacuation.

- No adsorbents required: Reduces waste and maintenance.

- Eco-friendly: No air pollution or chemical residues.

- Compact and mobile: Can operate directly at the transformer site.

- Energy-efficient: Low electricity consumption and quiet operation.

- High purification efficiency: Excellent oil quality even after one cycle.

Portable transformer oil dehydration units like Dry Core are designed for on-site use in substations, power plants, and transformer service centers. They can process hundreds of gallons per hour, restoring the dielectric strength of aged or wet transformer oil. This extends equipment lifespan, minimizes failures, and improves overall system reliability.

The transformer oil dehydration unit Dry Core represents a modern and efficient solution for maintaining transformer insulation systems. By utilizing advanced thermal vacuum drying, it removes all forms of moisture — from bound to emulsified — ensuring that transformer oil retains its essential insulating and cooling properties.

Keeping transformer oil in excellent condition is not just maintenance — it’s an investment in system reliability.